Cara kanggo nambah resistance nyandhang saka outsole

Cara kanggonambah resistance nyandhangsaka outsole,

senyawa, EVA, nambah resistance nyandhang, metu tunggal, sol sepatu, TPE, TPR,

Katrangan

Masterbatch anti-abrasion (Agen anti-nyandhang) NM-1Y minangka formulasi pelletized kanthi polimer Siloxane 50% UHMW sing disebar ing SBS. Iki dikembangake utamane kanggo sistem resin sing kompatibel karo SBS utawa SBS kanggo nambah resistensi abrasi barang pungkasan lan nyuda nilai abrasi. ing termoplastik.

Dibandhingake karo aditif Silicone / Siloxane bobot molekul sing luwih murah, kayata lenga Silicone, cairan silikon utawa aditif abrasi jinis liyane, SILIKE Anti-abrasion Masterbatch NM-1Y samesthine bakal menehi properti tahan abrasi sing luwih apik tanpa pengaruh kekerasan lan warna.

Parameter dhasar

| jeneng | NM-1Y |

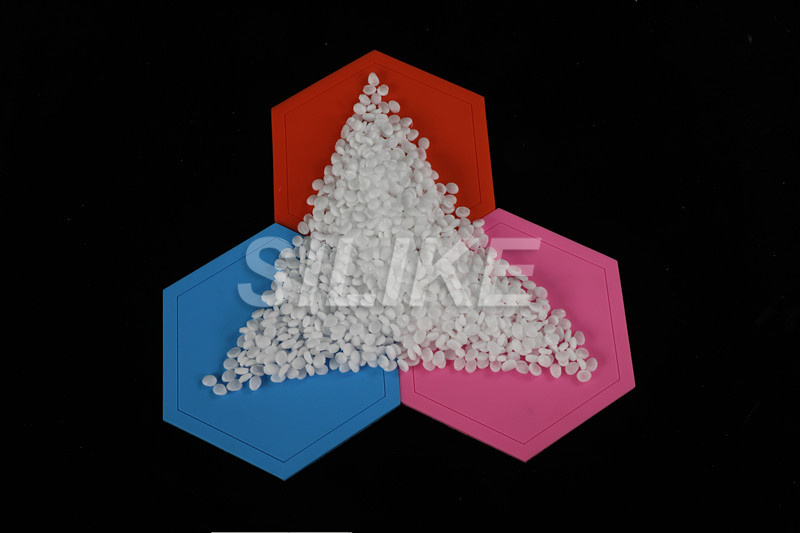

| Penampilan | Pelet putih |

| Kandungan bahan aktif% | 50 |

| Resin pembawa | SBS |

| Indeks leleh ( 190 ℃, 2,16KG ) g/10min | 1.50 (nilai khas) |

| Dosis% (w/w) | 0,5~5% |

keuntungan

(1) Ngapikake resistance abrasion kanthi ngurangi nilai abrasi

(2) Nyedhiyakake kinerja pangolahan lan tampilan item pungkasan

(3) Ramah lingkungan

(4) Ora ana pengaruh ing kekerasan lan warna

(5) Efektif kanggo tes abrasi DIN, ASTM, NBS, AKRON, SATRA, GB

Aplikasi

(1)TPRalas kaki

(2) alas kaki TR

(4) plastik liyane sing kompatibel karo SBS

Carane nggunakake

SILIKE Anti-abrasion masterbatch bisa diproses kanthi cara sing padha karo operator resin sing didhasarake.Bisa digunakake ing proses campuran leleh klasik kaya extruder sekrup Single / Twin, cetakan injeksi.Campuran fisik karo pelet polimer prawan dianjurake.

Rekomendasi dosis

Nalika ditambahake menyang SBS utawa termoplastik sing padha ing 0,2 nganti 1%, proses pangolahan lan aliran resin sing luwih apik, kalebu ngisi cetakan sing luwih apik, torsi extruder kurang, pelumas internal, release cetakan lan throughput sing luwih cepet;Ing tingkat tambahan sing luwih dhuwur, 2 ~ 10%, sifat permukaan sing luwih apik dijangkepi, kalebu lubricity, slip, koefisien gesekan sing luwih murah lan tahan mar / gores lan abrasion sing luwih gedhe.

Paket

25Kg / tas, tas kertas kerajinan

Lumbung

Transportasi minangka bahan kimia sing ora mbebayani.Simpen ing papan sing adhem lan kanthi ventilasi sing apik.

urip beting

Karakteristik asli tetep utuh sajrone 24 wulan wiwit tanggal produksi, yen disimpen ing panyimpenan sing disaranake.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch, Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnAnti-abrasion silicone masterbatches overcome the disadvantage in processing and properties of traditional additives, which has much better dispersity in resin, and with more durable abrasion resistance, better flow ability, and demolding. It can be easy to solve problems like bubbles, black lines, sticky molds, and so on.

GRATIS TAMBAHAN SILIKON LAN SAMPEL Si-TPV Luwih saka 100 KELAS

jinis sampel

$0

- 50+

gelar Silicone Masterbatch

- 10+

kelas Silicone Powder

- 10+

gelar Masterbatch Anti-gores

- 10+

gelar Anti-abrasion Masterbatch

- 10+

kelas Si-TPV

- 8+

grades Silicone Wax

-

Telpon

-

E-mail

-

WeChat

-

Ndhuwur

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur